Most people tend to wonder and ask, “What is a winch?” A winch is a mechanical device used for hauling or lifting. It is made of a rope, chain, or a cable wound on a horizontal and rotating drum.

It is turned by either a crank or a motor. A winch is mounted at the rear of a tow vehicle. Winches help people maneuver objects for millennia. They are ancient as the reeks use winches while lifting heavy objects and in major architectural projects such as hoisting bridges.

A winch consists of a spool attached to a hand crank in its simplest form. The winch working principle is: from a car to the power-driven motor, the motor drives a rotating drum, which operates the driving shaft. The shaft then drives a planetary gear generating a vigorous torque.

Various Types of Winches

Those who go off-roading with their vehicles know how it feels to have their car stuck in the mud. If your vehicle were in the same situation, you would be stranded if there was no one to help you. This is one of the many cases whereby a winch would come in handy.

There are different types of winches, and it is prudent to get one that suits your vehicle accordingly. The type of winch you choose will depend on many factors. Weight is one major factor to consider when using a winch.

Certain winches are only capable of handling 500 pounds, while some can handle more than that. Most of the basic winches can be purchased online for as cheap as $100. It will depend on the winch’s durability, load capacity, its ease of use and other factors.

This article will discuss the various types of winches to help you decide on which one suits your needs best. Here are the most common types of winches you will find in the market:

1. Air Winch

An air winch is powered by air pressure, but they are super powerful winches. They are often used for bulky items in construction sites. Typically, air pressure is fed from an air compressor in the winch to the motor drive using an airline. Once it activates the drive mechanism or motor powers the cable drum making the winch to effectively lower or raise the attached load.

A conventional air-powered winch creates a lifting force via a series of gear reductions. It may as well be referred to as an air-hoist or air-tugger. They are safe when compared to fuel-powered or hydraulic winches. Their controls provide precise handling when lowering, lifting, or even pulling a load in various industries.

In the construction, oil and gas, and maritime industries, these winches are often preferred to other types of winches. This preference often is due to their durability, safety, and versatility.

Air winches with a 1000 to 2000 lbs. load capacity have automatic band brakes, a radial piston motor, and remote control. Air winches with a load capacity of 4,000 to 10,000 lbs. feature three different air motors that help provide a range of speed, capacity, and air consumption options.

2. Snubbing Winch

This type of winch uses a spool positioned at a 90 degrees’ angle. It may have a retractable configuration like a typical winch, but it does not have a crank handle. Tail lines are used to reel line or tighten it. A little tension is usually formed after the application of force stops, and the winch is supporting all the weight.

A controlled release of pressure is possible with this winch. The snubbing winch has a vertical spooling system. The tail line is used when pulling the winch cable. The winch is also used in larger applications to retrieve and supplement tension on the main winch mechanisms.

Its main specifications are Antal standard snubbing, weight of 193 gr, four by 6 mm fasteners, 66 mm height, a base diameter of 80 mm, and a drum diameter of 51mm. It is excellent for lifting motor lifts and davits. Most winch boats mostly use a snubbing winch.

The pressure is controlled using some operators that circle the ratcheted spool. The friction produced by the movement of the lines helps much when controlling pressure. This device is used to control some ropes and sail on dinghies or the small sailing boats.

3. Electric Winch

Electric winches have become one of the fastest-growing produces in the market that is increasingly becoming flooded with a myriad of choices. However, its duty cycle is usually limited by your vehicle’s battery life. While operating an electric winch, it may be advisable to run your engine to prevent it from draining fully.

All winches have motors that power or drive the drum, which then spools the wire. An electric winch is powered by electricity. An electric winch is powered by both the car battery as well as anther battery that can operate independently from the car battery.

Electric winches are by far more universal. They are also much easier to remove or install and often may include more features than hydraulic winches. An electric winch has a lot of pulling power due to a lower gear ratio.

Premium battery units such as spiral cells or marine are designed to serve a dual purpose. They can be used to start and as deep cycle batteries. Getting the highest-rated and biggest battery can help you a lot in powering a winch in recovery situations. At times, some gearheads may add a second battery to their vehicles that are meant to be for winching only.

4. Hydraulic Winch

A hydraulic winch is a machine often used for heavy-duty applications. It delivers high strength, high efficiency as well as commendable durability. Typically, it uses hydraulic fluid in its functioning.

According to various functions a hydraulic winch performs, it can be divided into hydraulic cable pulling winch, hydraulic towing winch, hydraulic lifting winch, hydraulic anchor winch, and hydraulic mooring.

Since hydraulic winches are considered heavy-duty machines, they can be adapted into onshore and offshore applications. The hydraulic pump typically makes lifting of hefty loads more comfortable and safer.

A hydraulic winch is usually connected to the engine of a vehicle via the hydraulic pump. The hydraulic pump, in turn, powers a hydraulic motor. These winches can run whenever the vehicle engine is running, and they have a great deal of power.

An extra advantage of these winches is that they can work even when they are entirely submerged in water. A marine hydraulic winch is best suited for heavy-duty marine applications such as towing, anchoring, lifting, and mooing operations.

They come in a range of sizes, capacities, and styles to suit various customer preferences. The best quality hydraulic winch will assure a lifetime of efficient service.

5. Glider Winch

The glide winch is powered by fuel such as petrol, diesel or LPG. It is mainly used for launching a plane or even a glider. It is a super powerful winch that can pull cables of a length of up to 1600 meters. It is usually joined to a glider or plane and then pulled up to around 600 to 800 meters, which is the appropriate length required for gliding.

An engine powers the winch while on the ground. A long cable connects the glider winch to another release mechanism that is found under the glider. When someone activates the winch, the plane gets pulled along the ground towards the winch and then takes off, while climbing rapidly.

The glider winch often can retract at shocking speeds, and with the help of some compressed air, they can make a flight airborne in just a few seconds. They are not common, considering not as many people can afford to buy planes or gliders. However, it is still essential that you know how it functions. Also, they are rarer in the USA than any other part of the world.

6. Lever winches

These are winches that apply self-gripping jaws rather than spools to move a rope or wire through the winch. It is powered by a handle that moves back and forth. They allow one person to move heavy objects weighing tons.

The lever winch handle is often used for cranking. Alongside the air winch, it is also often used in construction sites. It is also commonly referred to as a hand winch. The most common band names are Griphoist and Tirfor.

A lever winch can as well be applicable in lashing and tensioning loads or transport. They have an added advantage of being able to lift in various positions, including vertically and horizontally. However, chain hoists can only be used vertically. Lever hoists may be used for lashing commonly in the transport industry.

Any certified lever and chain block is manufactured to lift a specific working load limit, for instance, 2 tons. The total weight to be lifted should not exceed this limit. Often, the working load limit is displayed clearly on the side of the hoist along with the serial number and manufacturer.

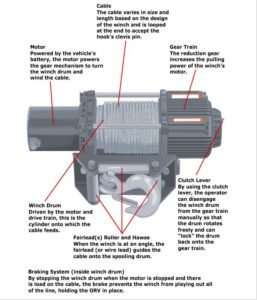

Parts of Winches

Getting to know the various parts of a winch helps the user to understand its functionality as well as the functional area of a winch. It is also crucial as it helps one to identify parts that are likely to cause the failure of a winch.

Although all winches have similar parts, most of them tend to differ in type, quality, build mechanism, and strength. Some winches use power while others are manual. However, despite the operation the differences, their parts are the same. A winch has several components, which have unique purposes to aid in a broader goal.

1. Cable

The cable is typically the first thing that should come to mind when talking about a winch. The cable wire usually has a hook on one end, and it pulls, drops, or lifts loads. The diameter and manufacture quality decide its drawing power or strength.

It is often made of steel or synthetic materials. The most popular metal used is galvanized steel. This is because metallic ropes tend to have a very high tensile strength, thus enabling users to lift hefty loads. Synthetic fiber is also a great option, just like steel. It can as well withstand rust and harsh weather conditions.

2. Drum

This is the round, drum-like part of a winch whereby the winch cable feeds. The drum usually rotates with the aid of a motor. The motor enables the winch cable to unwound or wound onto itself. A manual switch helps the drum to stop spooling and hold the wire in the preferred position, depending on its user.

The drum typically determines how easily the winch cable can be spooled with the help of the motor and gear train. The diameter of the drum varies, especially with the size of the winch, type, and requirements.

3. Motor

The motor is considered the backbone of the winch. All other parts help in pulling things, whereas the motor drives them. The DC motor in electric winches is usually either a series wound motor or a permanent magnetic motor. The coils in a motor are known as an armature. They are enclosed in a set of magnets or in another set of reels.

This enclosure formed is called the stator. When electricity passes, the stator produces some magnetic field and then rotates the armature. For permanent magnetic motors, a lot of battery power is used. They are thus suitable for lifting or pulling light to medium weights.

4. Gear Train

This part controls the speed of the motor and hence that of the drum as well. A gear reduction ratio increases the pulling power and efficiency of the winch. Typically, there are three gear types used in a winch.

A planetary gear system features a gear system that is designed like a planetary system. These gears include either two or more outer gears that revolve around the central gear. The spur gear has gears whose teeth are aligned parallel to each other. They have similar efficiency to planetary gears.

Worm gear trains are considered the strongest of the three, and they can apply self-brakes when overloaded.

5. Fairlead Mechanism

Usually, a high chance of lateral movement of the winch rope exists when it is pulling objects. This may cause fatal accidents or injuries. Therefore, the fairlead mechanism is installed on a winch to prevent such movement.

A fairlead may as well prevent mechanical wear of the rope while still enabling a free and smooth spooling. However, the fairlead build type varies depending on the type of cable used. For synthetic cables, a hawse fairlead is used, while for a steel cable, a roller fairlead is used. It is always better to be safe than sorry.

6. Battery

A battery is commonly used in electric winches. An electric winch uses both the battery of the vehicle and its inbuilt battery. Your vehicle’s battery life usually limits the duty cycle of a winch. While operating an electric winch, it may be advisable to run your engine to prevent it from fully draining.

Premium battery units such as spiral cells or marine are designed to serve a dual purpose. They can be used to start and as deep cycle batteries. Getting the highest-rated and biggest battery can help you a lot in powering a winch in recovery situations.

Other Parts

Depending on the ear system, winch-type, and manufacturer, a winch may or may not have other parts. These parts are such as wireless remote control, braking system, clutch system, waterproofing, or two planetary ear systems winches solenoids.

How Does a Winch Work?

Majority of the people do not go thinking about towing winches or even winches at all. It is crucial to understand the primary winch working principle for one to appreciate the essence of these machines. A winch, therefore, is a mechanism that winds wire around the drum while maintaining a steady tension in the wire.

The winch working principle is: from a car to the power-driven motor, the motor drives a rotating drum, which operates the driving shaft, and the shaft drives a planetary gear generating a strong torque.

The various parts of a winch come together to make it work. The cable wire is usually pulled out and attached to the object that one would like to tow. After it is attached, the motor is then turned on, and it starts to pull the cable back towards your vehicle and neatly around the winch drum.

First, a winch ought to be switched into the free spool mode to enable you to easily roll out the rope and fix it onto an anchor object with a higher capacity than the winch. Typically, a heavy truck is your best bet or even a four-wheel-drive vehicle.

After the cable is attached, lock the winch. Using hand-held controls of the winch, you should then feedback the rope into the winch drum until it is pulled taught. If you can start the winch while slightly pressing the gas pedal of the stuck vehicle, it would be great.

Any off-roader will tell you how easily a winch can get you out of a sticky spot in mud when everything else has failed. A winch in your tool kit would come in handy to prevent you from having to call up a tow truck.

Tow winches are an example of towing equipment that is strong enough to tow both cars and trucks. A towing winch typically pulls a vehicle onto the towing platform or up he towing sling. The serious off-roaders use winches to pull themselves out of the mud.

Most winches have automatic brakes to increase their efficiency. If you have ever asked yourself, “How does a hand winch work?” worry not for the principle behind its working is clearly explained here. Some of the winches are large and bulky but you can also get compact and portable winches. A small portable winch is convenient and easy to carry around.

The hand winches are controlled by a ratcheting lever or ratcheting crank that winds the winch cable onto the spool while the winch pulls a load. Also, the ratchet prevents kickbacks if the winch is under pressure. When used appropriately, hand winches give a mechanical advantage, thus enabling the user to move loads weighing even in tons.

You should always inspect winch attachments that are at the load end and anchor before you start working on the winch. Turning the crank handle tightens the cable. To pull the load, you should continue working the lever or crank. Ensure that you are at a safe distance when operating the winch. It is also important to learn the safety measures of operating a winch.

In case you wonder how does a winch brake work automatically, hey are manufactured this way. They are also self-locking hence making them perfect for vertical lifting. The operator simply cranks the handle clockwise or anticlockwise to raise and lower the load.

That is the basic working of a winch. Moreover, safety should be your key concern, and here, common sense mostly applies. Once you get the right winch for your vehicle, go through the guidelines to see other guidelines in using that specific winch. With this understanding, the winching process will not only be easy for you but also safe.

Conclusion

A winch is a useful tool in our daily lives, although often underestimated by many. Most importantly, it makes work easier especially when you need to pull a vehicle or heavy load. With that said, I hope you can now answer the questions, what is a winch? How does a winch work? If you are yet to buy a winch, this article should have all the essential information that you require before making a decision.

There are lots of applications for the machine. It would be advisable to go for a winch that suits your preferences and needs as well. Where necessary, you can always ask the experts. There are many types and brands out there; hence you might need to do more research before you get the perfect one.

Also, importantly, always be careful to ensure your safety as well as that of those around you. Always have a winch around you because you might never know when you may need one. It is better to have a winch and not need it, than to need the winch when you do not have it.